Reverse Engineering Industrial Parts

Reverse-engineering industrial parts is essential to industries and manufacturing systems, and is very common in modern industries. The system also receives regular mechanical services, including dimensional measurements to cover damages and losses and immediately begin corrective measure, which can prevent additional economic incidents and lengthy machinery and industrial equipment order stoppages. Broken parts in systems or equipment should be immediately replaced with functional parts to minimize stops. Reverse-engineering industrial parts in societies is directly related to many industries. There are various techniques for this engineering approach. Some equipment meet certain standards and can be supplied and replaced. However, other stock parts are available to manufacturers on the market. This engineering approach becomes useful when facing production stops in factories or encountering problems with purchasing and importing necessary equipment. The high cost of procuring these components from overseas also creates many production line stoppages. Due to these problems, industrialists and manufacturers cautiously use reverse engineering. Ultimately, reverse engineering industrial parts is a great approach to resolving these problems. At present, manufactures need to consider the production of basic, key, and irreplaceable components. These components are replaced if damaged during stoppages, repairs, and optional overhauls for reverse engineering. There are various reverse engineering methods, one of which is to produce and order prototypes.

The Applications and Advantages of Reverse-Engineering Industrial Parts

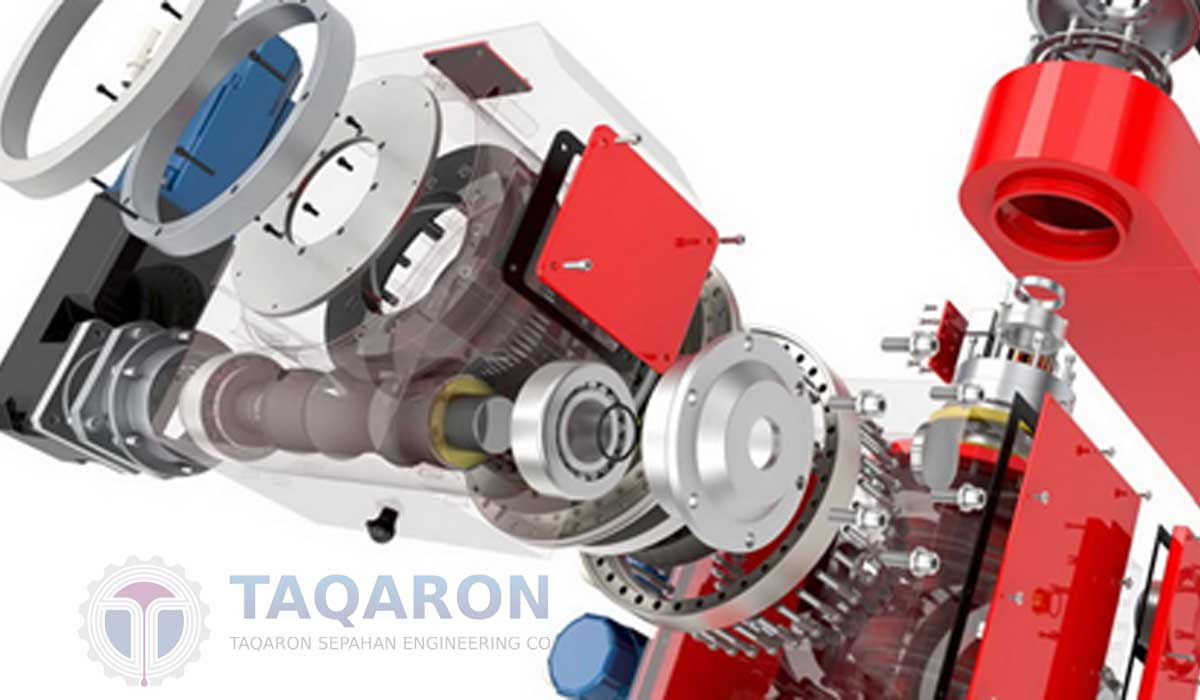

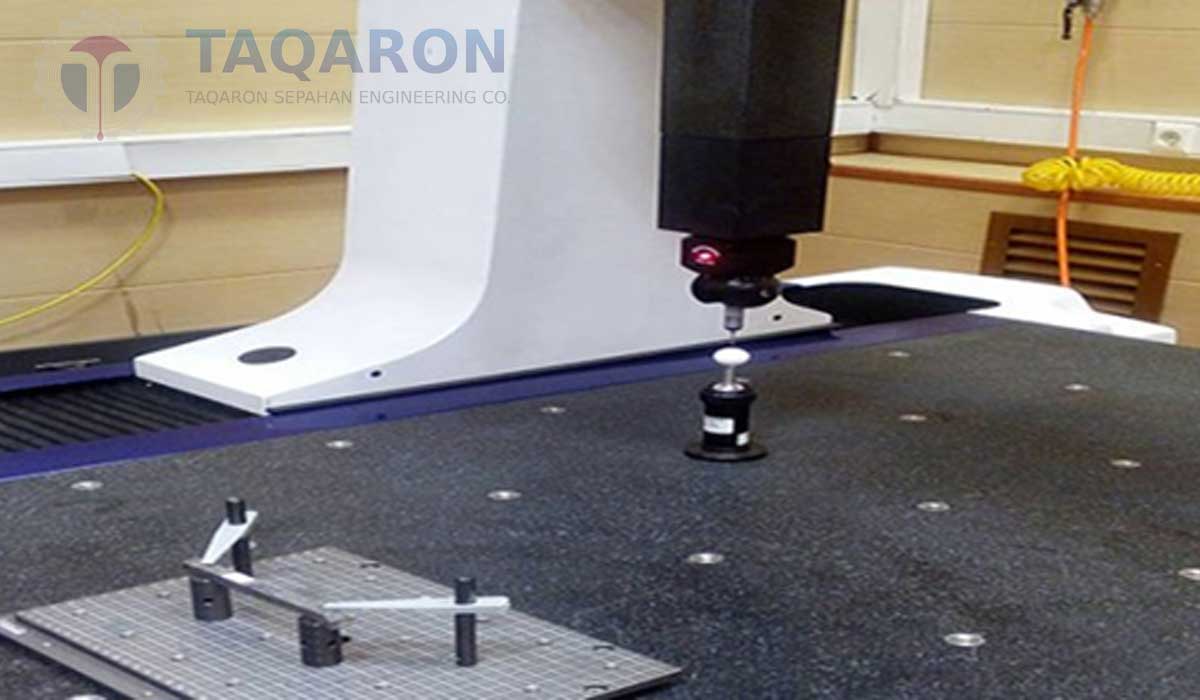

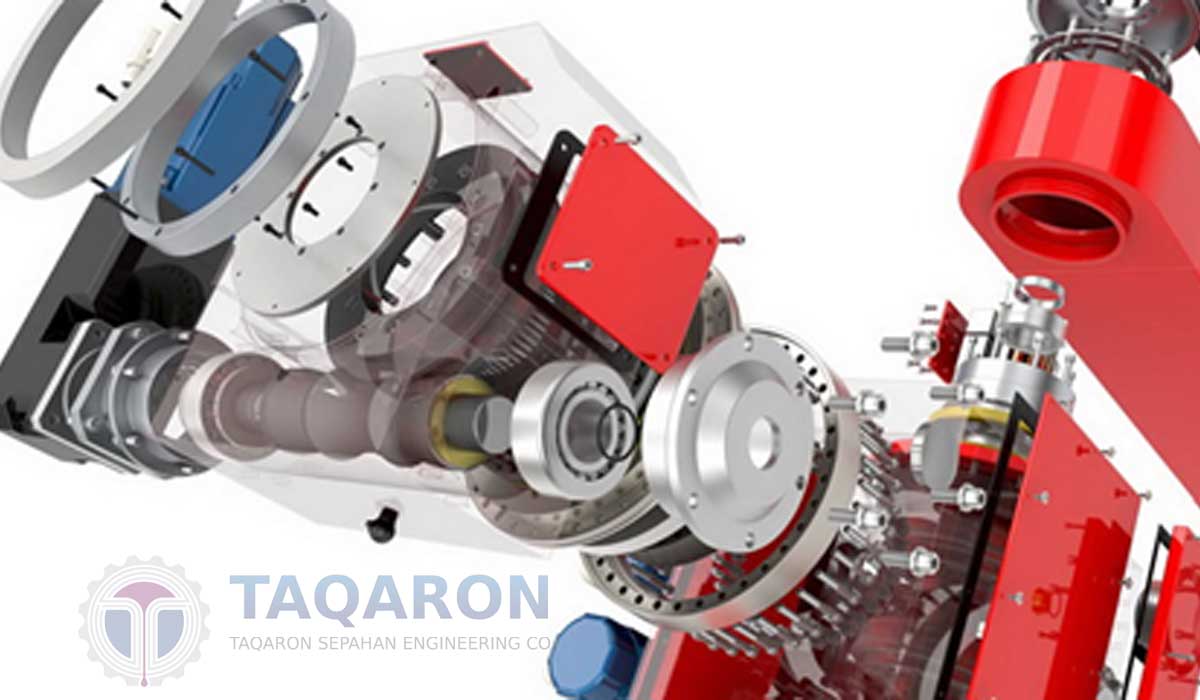

The applications of reverse-engineering include the industrial machines and parts used in oil, gas, and petrochemical industries, medical products and equipment, home appliances, aviation, and production line machinery. By reverse-engineering industrial parts, large companies investing in RE have reduced their prototype production and order times. The lack of access to 3D digital CAD is an important parameter in selecting and using reverse engineering to manufacture components. The stages of building and ordering industrial components are as follows. In this method, the actual part close to the original plan or model should be found to start part manufacturing in stages. A widely-used and currently-available method was used to measure industrial components. Then, with a focus on the machine’s overall shape, the holes and pores and production tolerance was selected according to new methods such as CMM, VMM, and more. Scanners quickly provide CAD plans and the model and pattern required for production to engineers. With new part design methods, few people refrain from choosing modern part manufacturing methods. Therefore, small-scale parts for products are measured partially by drawing plans and using the latest models. Since modern methods improve the precision of these machines and methods and accelerate part manufacturing, digital 3D measurement machines can design and manufacture part models in the shortest possible time and very high precision.

Reverse-Engineering Machinery Production

Like reverse engineering industrial parts, reverse-engineering machinery production should be done according to digital measurements of industrial parts. Actual surfaces are converted into a digital format, and according to the method, the digitalization process, point of cloud mapping, and manufacturing is done in software (e.g. CAD). The primary model of digital measurements is 3D scanning, which allows for transferring and using spatial point measurements to CAD. Scanners output clouds of points, which constitute the part’s surface points. However, there are other measurement systems available. One such measurement device is outfitted with optics; and there are other devices outfitted with laser and touch technologies. Reverse-engineering is a more economical means of mass producing and ordering industrial components and machinery. In fact, the reproduction technology is an optimal and useful process for developing the equipment existing in the country. This engineering approach helps individuals to better handle a process related to a problem. Currently, half the engineers who work in knowledge-based enterprises, universities, and entrepreneurial workshops use this technology and are satisfied with its application and services. Thus, they bring success to their nation. Reverse-engineering can transform a society’s economy. Therefore, learning this approach requires extraordinary effort, an honor that brings the country growth and prosperity. Most projects using reverse-engineering industrial parts consider the cloud of points or 3D scan of reverse engineering, a reverse-engineering stage in SolidWorks and Catia. Parts that should be produced using 3D scan of casings and surfaces are used in most indigenous projects.

Production Applications of Reverse-Engineering Machinery

There are many arguments for using reverse-engineering machinery for producing and ordering agricultural machines. However, prototyping a foreign system requires meeting certain rules and regulations that will transfer technology for manufacturing machinery into the country. There are many Iranian companies for manufacturing machines and parts that offer consultation and help you in designing, sampling, and producing industrial systems. Reverse engineering industrial parts is initially a question of engineers’ ability to produce a machine from pictures or reverse-engineering videos. If there is no physical sample of a part you intend to reproduce, all you have to do is spend more time and money. Therefore, in addition to producing a product or machine from a catalog or its operational video, you also need to see a mixture of reverse-engineering and design. Although it is possible to produce functional and moving mechanisms from images and training clips, it is still preferable to design and produce components using modern design methods in industrial part reverse-engineering. Individuals with engineering know-how may find difficulty in determining which products to make using this method. It is worth mentioning that the devices and products you intend to mass produce are ideal candidates for reverse engineering. Ultimately, the machinery and products that do not require plastic molds or casting are also good candidates for reverse engineering processes. Accordingly, parts require up to 10% scanning, and the remainder is measured and reverse-engineered manually. Engineers in this field strive to complete such projects and call companies with 3D scanners for help. Reverse-engineering is a complex and difficult process that requires familiarity with production methods, materials science, mechanics, and mechanisms, including 3D scanning and cloud of points.